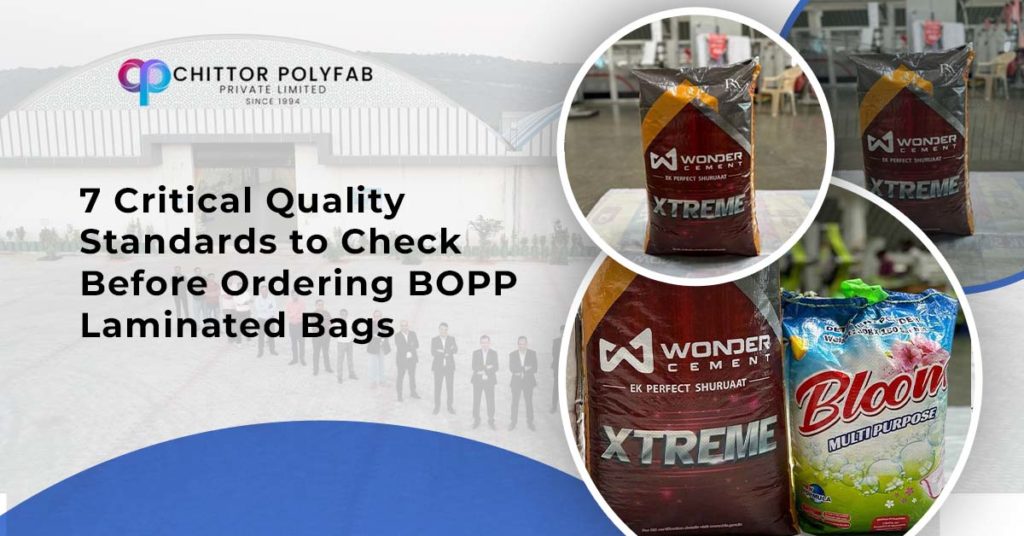

7 Critical Quality Standards to Check Before Ordering BOPP Laminated Bags

Why Quality Checks Matter Before Ordering Ordering BOPP laminated bags without verifying technical standards can expose your business to avoidable risks such as product damage, delamination, weak seams, or inconsistent print quality. These bags are widely used for grains, fertilizers, animal feed, FMCG products, and industrial goods, where durability and presentation both matter. Performance depends …

7 Critical Quality Standards to Check Before Ordering BOPP Laminated Bags Read More »