In today’s packaging world, the demand for durable and versatile packaging solutions has never been higher. Companies need packaging that not only protects their products but also ensures efficiency, cost-effectiveness, and sustainability. Multi-layered PP woven bags have become a go-to option for industries that require reliable packaging for a wide range of products. From construction materials to food products, these bags offer unmatched durability, flexibility, and strength. In this blog post, we will explore the numerous benefits of using multi-layered PP (Polypropylene) woven bags and how they contribute to enhanced durability in industrial packaging.

What Are Multi-Layered PP Woven Bags?

Before delving into the benefits, it’s essential to understand what multi-layered PP woven bags are and how they differ from traditional packaging options.

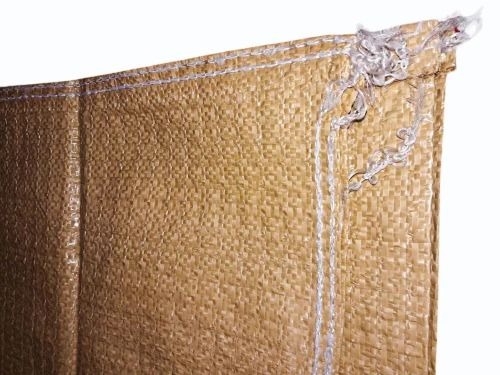

Multi-layered PP woven bags are constructed from several layers of polypropylene fabric. Polypropylene is a thermoplastic polymer known for its robustness and versatility, which makes it ideal for creating woven bags. These bags are designed to hold bulk items, offering superior strength and protection against physical damage. The multiple layers enhance their resistance to wear, tear, and other environmental factors.

These bags are commonly used in industries such as agriculture, construction, and food packaging, where durability is a critical requirement. Now, let’s dive deeper into the advantages of using multi-layered PP woven bags.

1. Enhanced Durability and Strength

One of the primary benefits of multi-layered PP woven bags is their exceptional durability. Unlike single-layer bags, multi-layered bags offer increased strength, which makes them suitable for carrying heavy and bulky items. The additional layers of fabric provide added protection against punctures, abrasions, and tears. This makes them ideal for packaging materials like cement, fertilizer, grains, and pet food.

The structure of multi-layered bags ensures that they can withstand high levels of stress and pressure without compromising their integrity. For example, when transporting materials like sand or gravel, the extra layers prevent the bag from breaking under heavy weight, which could otherwise lead to product loss and wastage.

2. Improved Protection Against External Factors

Multi-layered PP woven bags are not only durable but also offer excellent protection against external factors such as moisture, dust, and UV rays. These bags are often coated with a layer that provides water resistance, preventing moisture from penetrating the bag and damaging its contents.

In industries like agriculture, where moisture can lead to mold growth and spoilage of products, the ability to keep water out is vital. Multi-layered PP woven bags are designed to keep your goods safe from moisture, making them a reliable choice for packaging food products, chemicals, and fertilizers that are sensitive to environmental conditions.

Additionally, multi-layered bags are often treated to provide UV protection, which helps prevent degradation from sunlight exposure. This makes them suitable for outdoor storage and transportation, ensuring that the products inside remain safe even in harsh weather conditions.

3. Cost-Effectiveness

When compared to other types of industrial packaging, multi-layered PP woven bags are often more cost-effective. While they may have a slightly higher initial cost than single-layer bags, their durability leads to reduced costs in the long term. The increased strength and ability to withstand damage mean fewer replacements, less product loss, and reduced shipping costs due to fewer instances of damaged goods.

Moreover, these bags are reusable and can be recycled, further increasing their value. Businesses can get multiple uses out of a single bag, reducing the overall cost of packaging materials. Additionally, the long lifespan of multi-layered PP woven bags makes them a more sustainable choice when compared to other less durable packaging options.

4. Customizability for Different Needs

Another significant advantage of multi-layered PP woven bags is their customizability. These bags can be tailored to meet the specific needs of various industries. Whether it’s size, color, printing, or the inclusion of special features like handles or closures, multi-layered PP woven bags can be customized to suit a wide variety of applications.

For businesses that require branding or product-specific packaging, the ability to print logos, labels, and product details on the bags makes them an ideal choice. Custom printing also helps enhance the visibility of the brand, which can be beneficial for marketing purposes.

5. Sustainability and Environmental Impact

In today’s eco-conscious world, businesses are increasingly seeking sustainable packaging solutions. Multi-layered PP woven bags contribute to sustainability efforts in several ways.

Firstly, the durability of these bags means they have a longer lifespan than single-use bags or less durable packaging alternatives. Fewer replacements are required, which helps reduce waste. Furthermore, PP woven bags are recyclable, and many companies are using recycled PP to manufacture these bags, which reduces their environmental impact.

Another factor to consider is the ability of these bags to be reused for multiple cycles. This reusability reduces the overall consumption of resources and helps businesses lower their carbon footprint, contributing to a more sustainable packaging solution.

6. Versatility in Packaging Applications

Multi-layered PP woven bags are incredibly versatile, making them suitable for a wide range of packaging applications. These bags can be used for packaging everything from grains, powders, and chemicals to building materials and pet food. Their strength and resistance to damage make them ideal for packaging both heavy and light products.

In the agricultural industry, for example, multi-layered PP woven bags are frequently used to pack and transport grains, seeds, and fertilizers. Their ability to protect the contents from moisture and pests ensures that products remain in optimal condition during storage and transportation.

In the construction industry, multi-layered PP woven bags are used to package materials like sand, cement, and gravel. These bags are strong enough to handle the weight of heavy products and can withstand the rigors of transport without breaking.

7. Easy to Handle and Transport

Despite their strength and durability, multi-layered PP woven bags are surprisingly easy to handle and transport. The flexibility of the material allows the bags to be folded or stacked, making them easy to store and ship. Additionally, the bags can be equipped with handles or lids for easy lifting and securing of the contents, making them user-friendly for both workers and customers.

Moreover, multi-layered PP woven bags are designed to be lightweight, reducing transportation costs. The lightweight nature of these bags doesn’t compromise their strength, making them an ideal choice for businesses looking to balance durability with logistical efficiency.

Conclusion

In summary, multi-layered PP woven bags offer a wide array of benefits that enhance their durability, performance, and versatility. From providing superior protection against external factors like moisture and UV rays to offering cost-effective and sustainable packaging solutions, these bags are an excellent choice for businesses across various industries. Their customizable nature, reusability, and ability to withstand harsh conditions make them one of the most reliable options available for industrial packaging.

If you’re looking for a packaging solution that combines strength, flexibility, and sustainability, multi-layered PP woven bags are the way to go. By choosing these bags, you not only protect your products but also contribute to a more sustainable and efficient packaging system.