In industries like agriculture, construction, and chemical manufacturing, choosing the right packaging material is crucial. Woven bag is one of the most commonly used packaging solution due to their durability, cost-effectiveness, and flexibility. But when it comes to heavy-duty packaging needs, businesses often face a common dilemma: Should you choose 3-layer or 5-layer woven bags?

Understanding the differences between these two bag types can help you make informed decisions that enhance product safety, branding, and efficiency.

What Are Multi-Layer Woven Bags?

Multi-layer woven bags are typically made of polypropylene (PP) fabric with additional layers to provide extra strength, protection, and functional benefits. These layers may include BOPP film, adhesive laminations, or protective coatings depending on the product’s needs.

A 3-layer woven bag consists of:

- Woven PP fabric (base layer)

- A lamination or film layer (often BOPP)

- An external coating or print surface

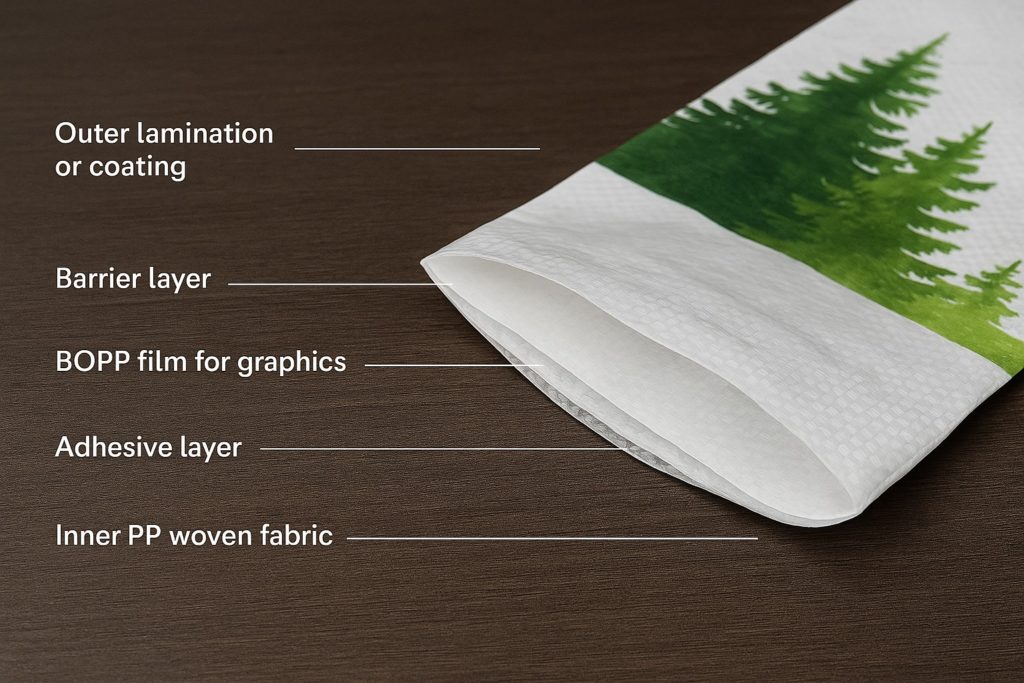

A 5-layer woven bag includes:

- Inner PP woven fabric

- Adhesive layer

- BOPP film for graphics

- Barrier layer (for moisture or chemical resistance)

- Outer lamination or coating

Each layer serves a distinct purpose in enhancing the bag’s structural integrity, durability, and branding capabilities.

Strength and Load-Bearing Capabilities

3-Layer Woven Bags: Sufficient for Mid-Weight Applications

3-layer woven bags offer reliable strength for products up to 25–35 kilograms. They are ideal for dry, non-reactive materials such as grains, pulses, flour, sugar, and animal feed. These bags are often used in domestic markets where packaging doesn’t undergo long transport cycles.

While they provide good tensile strength, 3-layer bags may not be suited for materials that require extended storage, high stacking, or extreme weather protection.

5-Layer Woven Bags: Built for Heavy-Duty Demands

5-layer woven bags are engineered to carry up to 50 kilograms or more. The multiple layers increase tear resistance, improve stability, and protect contents from external elements like moisture, heat, and UV rays.

Industries transporting cement, fertilizers, chemicals, or construction aggregates often rely on 5-layer bags for long-distance shipping and high-stress handling.

Protection from Moisture and Environmental Factors

Why Moisture Resistance Matters

For many industrial products—especially powdered materials or hygroscopic compounds—moisture is a major threat. Exposure can cause spoilage, clumping, or loss of chemical properties.

3-Layer Bags: Basic Moisture Defense

3-layer Woven bags offer limited moisture protection due to a single lamination layer. While sufficient for products with short shelf lives or indoor storage, they may not be reliable for outdoor warehousing or monsoon conditions.

5-Layer Bags: Superior Environmental Shield

With additional barrier films and tighter lamination, 5-layer woven bags provide enhanced protection against moisture, oxygen, and UV rays. This makes them a better choice for materials that need to be stored for weeks or months or transported across diverse climates.

Printability and Branding Opportunities

3-Layer Woven Bags: Good for Basic Branding

3-layer bags can accommodate flexographic or single-color BOPP printing. They are suitable for basic logo printing and product information but may not support high-resolution visuals or multi-color graphics effectively.

5-Layer Woven Bags: Premium Brand Presentation

The BOPP film layer in 5-layer bags is perfect for HD-quality, multi-color printing. This allows for vibrant product branding, promotional messaging, and barcode printing directly on the packaging—greatly enhancing shelf appeal.

If you are a brand looking to differentiate yourself in a competitive market, 5-layer woven bag offer a visual advantage.

Durability in Logistics and Storage

3-Layer Bags: Moderate Durability

3-layer woven bags can handle short-haul logistics and manual handling well. However, they might show signs of wear during automated stacking, rough loading/unloading, or long exposure to direct sunlight.

5-Layer Bags: High-Endurance Packaging

Thanks to the extra layers, 5-layer bags offer exceptional durability in both local and international logistics. Whether you’re shipping via road, rail, or sea—these bags maintain shape, prevent leakage, and reduce product wastage during transit.

Cost Considerations

Is Price a Deciding Factor?

3-layer woven bags are more affordable due to fewer materials and simpler manufacturing. They suit companies prioritizing cost-efficiency over long-term storage or premium branding.

In contrast, 5-layer woven bags involve higher production costs but offer better returns through enhanced protection, fewer losses, and brand differentiation.

Choosing between the two should depend on:

- Your product type and shelf life

- Storage conditions and logistics

- Target market (domestic vs. export)

- Branding and compliance needs

Industry-Specific Applications

Here’s a quick overview of where 3-layer vs. 5-layer woven bags are commonly used:

| Industry | 3-Layer Bags | 5-Layer Bags |

|---|---|---|

| Agriculture | Grains, pulses, seeds | Fertilizer, urea, pesticide powders |

| Construction | NA | Cement, fly ash, hydrated lime |

| Chemicals | Detergent, basic powder | Industrial chemicals, corrosion agents |

| Food & Beverage | Flour, sugar, rice | Salt, starch, export-grade edible items |

When Should You Choose Each?

Choose 3-Layer Woven Bags If:

- Your products are not highly sensitive to moisture

- You operate in local markets with basic handling

- You want an economical solution

- You don’t need full-color packaging

Choose 5-Layer Woven Bags If:

- Your product is heavy or has export requirements

- You need moisture or UV protection

- You want premium, multi-color packaging

- You are handling materials that need prolonged shelf life

Final Thoughts

Choosing the right woven bag impacts product quality, logistics efficiency, and even customer perception. While 3-layer woven bags are excellent for basic packaging, 5-layer woven bags offer a robust solution for demanding environments.

At Chittor Polyfab, we help businesses choose the ideal packaging for their industry. Whether you need standard woven sacks or advanced multilayer bags, we ensure quality, customization, and timely delivery.

Ready to upgrade your packaging?

Contact us today to speak with our experts and request a custom quote.