Types of cutting

Types of Cutting at ChittorPolyfab

At ChittorPolyfab, we understand that the precision and quality of the cutting process are critical for producing high-performance industrial packaging bags. Our cutting techniques ensure that each bag is crafted to meet exact specifications, with durable edges that maintain the integrity of the packaging. Below are the primary cutting methods we utilize to deliver top-quality industrial bags:

Blade Cutting

Blade cutting is one of the most traditional and precise methods used in the manufacturing of industrial packaging bags. At ChittorPolyfab, this technique involves using sharp, high-grade steel blades to cut through woven polypropylene or other materials. Blade cutting is ideal for producing clean, straight edges and is commonly used for large-volume runs where accuracy is key.

Advantages:

- Produces smooth, clean edges.

- Efficient for high-speed production.

- Ideal for standard industrial packaging shapes and sizes.

Heat Cutting

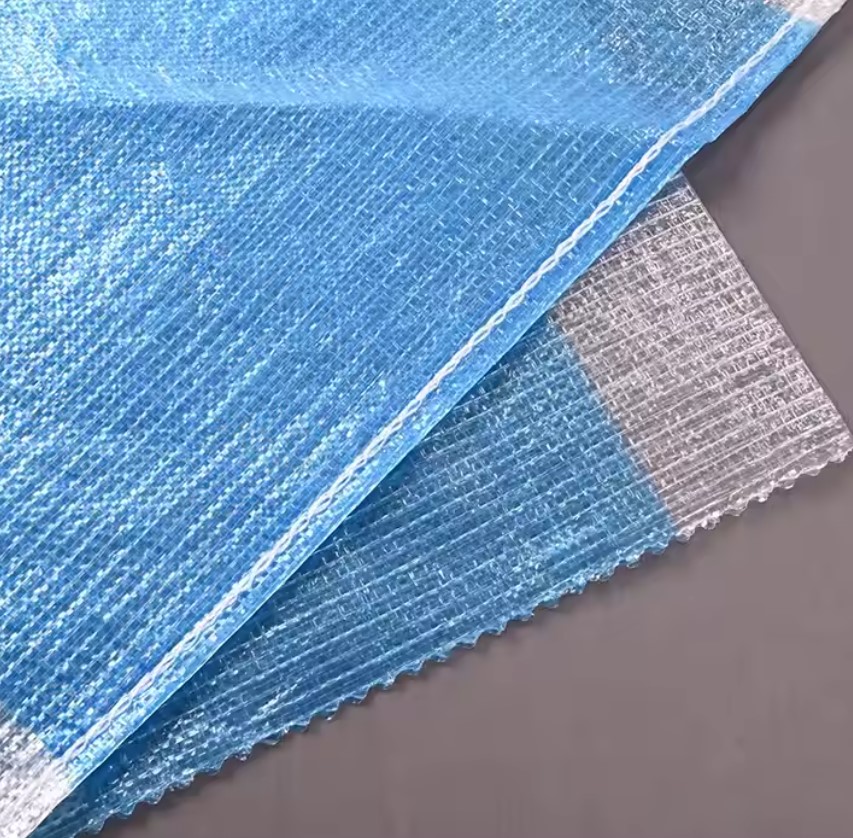

Heat cutting is a method where a heated blade is used to cut and simultaneously seal the edges of the bags. This is particularly useful for materials like polypropylene, as the heat prevents fraying and strengthens the edges. By using this technique, ChittorPolyfab ensures that each bag has reinforced edges that are resistant to wear and tear during transportation and storage.

Advantages:

- Seals edges to prevent fraying.

- Ideal for applications where edge durability is important.

- Suitable for a variety of bag sizes and types.

Heat Zig Zag Cutting

Heat zig zag cutting combines the precision of heat cutting with a unique zig zag pattern to create a more distinctive and stronger edge. This method is particularly beneficial for bags that require enhanced grip or flexibility at the seams. The zig zag cut not only strengthens the edges but also provides a visual distinction, making it easier to handle and stack the bags.

Advantages:

- Creates a reinforced, textured edge.

- Reduces slippage during stacking.

- Provides additional edge durability and visual appeal.

At ChittorPolyfab, each cutting method is carefully chosen based on the type of bag being produced and its intended use. Whether you’re looking for precision, durability, or a unique finish, our cutting techniques are designed to meet your packaging needs with excellence.